Some backround info:

This is a third member inc housing and axles I bought from an aftermarket supplier. The paint job on the housing was so poor that I had to take it appart to be able to mediablast the third member housing. I never took anything appart on the pinion assembly, just removed it from the carrier housing. I assembled the pinion to the housing using the same shims and sealer between lid/shim/housing. Then I adjusted the ring to pinion backlash to get the appropriate wear pattern. However the appropriate wear pattern gives me a backlash that is slightly outside the ring and pinion gear manufaturers specs. They say 0,007"-0,009".

A nother source on the internet states: Aftermarket gears 0,007"-0,010" and OEM 0,010"-0,017".

So in other words. Is this good enough or is the 0,009" upper limit from the ring/pinion gear manufacturer a rock solid limit.

I ended up at about 0,0098" with the wear pattern at the bottom of this page.. They can be compared to the wear pattern as it was delivered to me a few pictures above the end. Mine and as delivered is pretty close to each other

So is this good enough??

Thanks in advance!

Some old gasket on tube residue above. The o-ring was missing from the supplier.

All cleaned up for a new o-ring and some new gasket on tube.

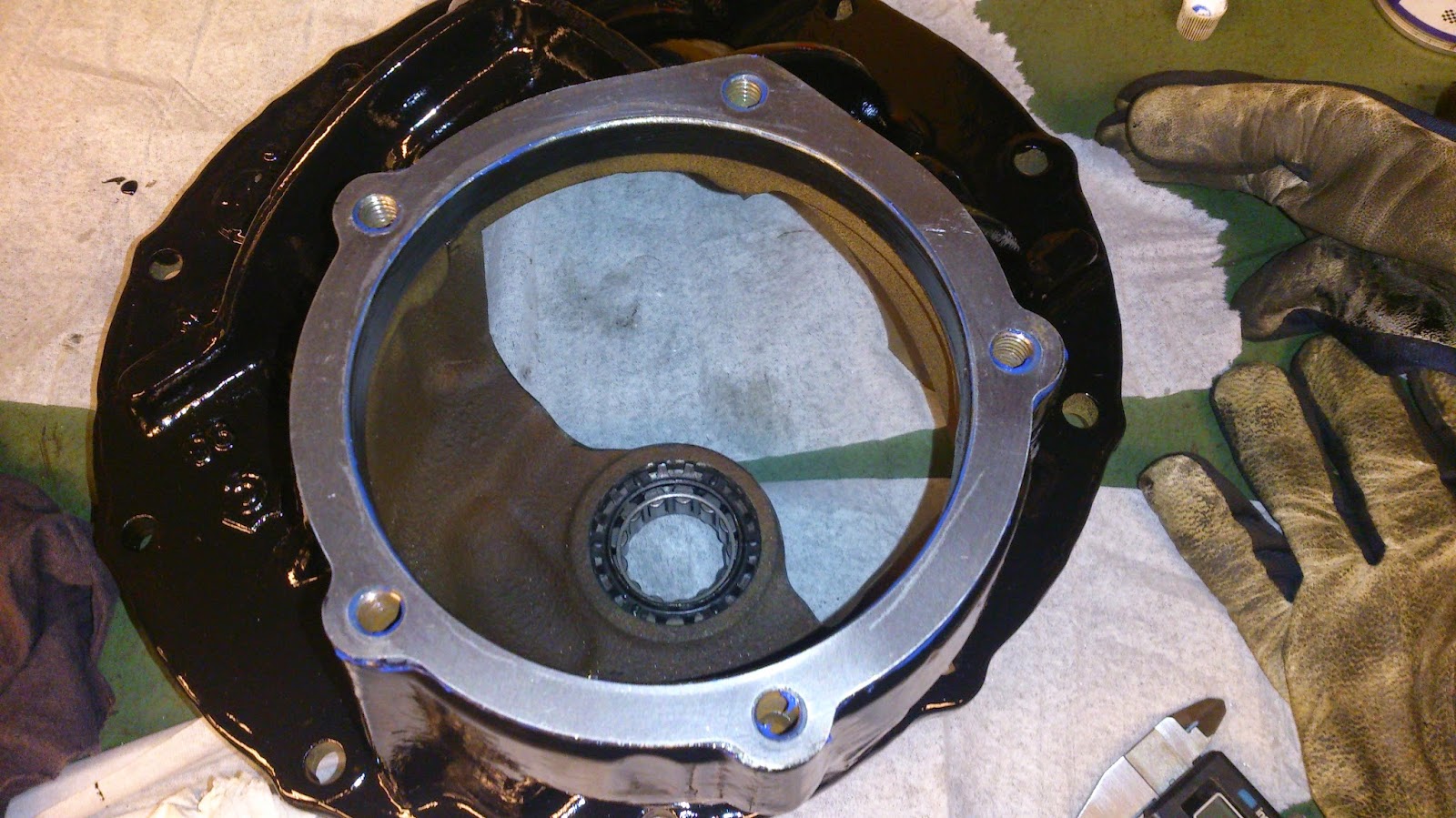

Bearing back in place together with the retainer.

A light coat of gasket on tube on both mating surfaces.

Shims all cleaned up and put in place. O-ring slot and o-ring mating surfaces lubed up with some grease.

Torqued down to 20 ft-lbs in first stage and then to 40 ft-lbs

Had forgotten to remove the old thread locking compound. So a small blanket to get the dirt on the right side.

Ring assemly in place and the adjuster nut hand tightened.

This picture is a bit missleading, the bearing caps where mounted and torqued down before I made any measurements.

This is the pattern as the third member was delivered to me, i.e before I took it appart for paint.

Some white oilbased color and some engine oil mixed to get some marker paint.

This pattern was achieved with a backlash of 0,0098". The ring and pinion manufacturer states 0,007"-0,009". A nother source on the internet states: Aftermarket gears 0,007"-0,010" and OEM 0,010"-0,017".

So in other words. Is this good enough or is the 0,009" upper limit from the ring/pinion gear manufacturer a rock solid limit.

UPDATE 2015-03-01

Final assembly ended up like this with a backlash of 0.0790 and with this pattern

.0098 is perfect, gear patern looks good as well , just remember clearence and backlash will begin to close up after unit begins to warm up from use. be sure to use a good quality gear lube. ( I recommend synthetic )

ReplyDeleteAs long as you have some reasonable amount of backlash to keep the gears from binding as they expand when hot, you're fine. Too much backlash is a bad thing as it will make the gears noisy. At .0098", I think you're just fine. I normally shoot for close to .010" on just about any axle I build. Your pattern looks good too. The really critical thing to watch when setting up gears is pinion depth. You want the pattern centered between the root and the top of the tooth. Position of the pattern between the heel and toe of the tooth is a function of backlash and isn't nearly as important. Run it!

ReplyDeleteBlueOvalRage